Laser Cutting

Precision and Versatility for Demanding Projects

Sheet metal processing is a key element of modern manufacturing and plays a crucial role in many industries. Laser cutting, in particular, has established itself in recent years as one of the most precise and efficient methods for processing sheet metal. This technique offers outstanding advantages in terms of accuracy, flexibility, and efficiency, enabling complex and demanding projects to be executed with the highest precision.

What is Laser Cutting?

Laser cutting is a thermal separation process in which a focused laser beam is used to cut materials such as metal, plastic, or glass. The laser beam is concentrated on a very small area, creating an extremely high energy density. This energy is focused on the material, causing it to melt, vaporize, or burn, thereby allowing precise cutting of even complex shapes and contours.

Advantages of Laser Cutting

Laser cutting offers numerous advantages over traditional cutting methods. One of the biggest advantages is the high precision achieved by the fine focus of the laser beam. This allows even very intricate and complex geometries to be cut cleanly and accurately. The cut edges are usually very smooth, requiring little post-processing, which significantly speeds up the production process.

Another trend in facade architecture is the integration of photovoltaic modules into metal panels. These "smart" facades can generate energy, contributing to the building's energy independence. When combined with advanced insulation and ventilation systems, such facade solutions significantly enhance the sustainability and energy efficiency of buildings.

Our Capabilities in Laser Cutting

We utilize state-of-the-art laser cutting technology to offer you the best solutions for your projects, ensuring precision and efficiency at every step of the process. Our capabilities include cutting a wide range of materials, from thin sheets to thick plates, with high accuracy and minimal waste. We are committed to delivering high-quality results that meet your specific needs and requirements.

Our high-performance laser cutting systems are characterized by high cutting speed and extreme precision. This enables us to achieve optimal results even for demanding projects requiring the highest level of accuracy. Additionally, our machines are flexible enough to seamlessly switch between different types and thicknesses of materials without compromising quality or efficiency.

Applications of Laser Cutting

Laser cutting is used in a wide variety of industries, particularly where high precision and fast turnaround times are required. For example, the process is used in the automotive industry to manufacture body parts, chassis components, and interior fittings. It is also an indispensable tool in mechanical engineering, electrical engineering, and medical technology for producing precise and high-quality components.

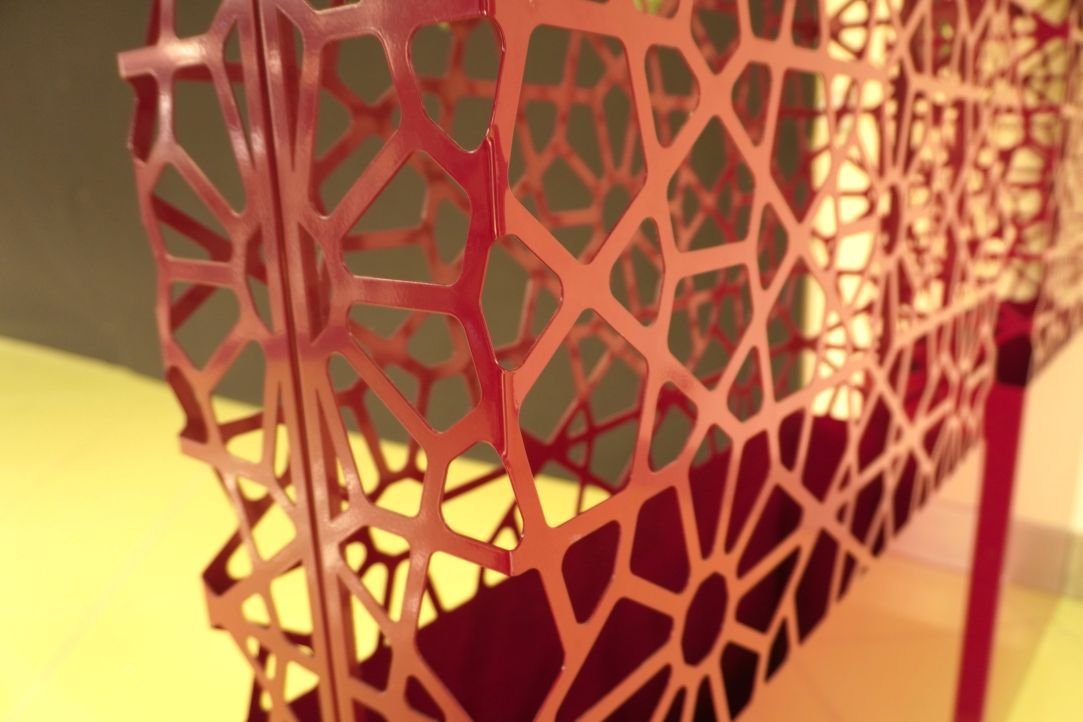

Another important area of application is the construction and architectural sector. Here, laser cutting is used to produce customized facade elements, decorative features, and load-bearing structures. The ability to cut complex and intricate patterns into metal opens up new creative possibilities for architects and designers.

Laser cutting has also gained importance in the art and design sectors in recent years. Artists and designers use the technique to create innovative and unique metalworks that impress with their precision and attention to detail.

Quality Assurance and Sustainability

Quality is our top priority. That's why we rely on the most advanced laser technology and highly trained personnel to ensure that every project is executed with the highest precision and care. Our quality management system monitors every step of the production process to ensure that the parts we manufacture meet our customers' exact specifications.

In addition to quality, we place great emphasis on sustainability. Laser cutting is a highly efficient process that minimizes material waste. The precise control of the laser beam allows the material to be utilized optimally, reducing waste. We also continuously work to optimize our processes and reduce the energy consumption of our machines to minimize our environmental footprint.

Conclusion

Laser cutting is a cutting-edge and versatile technology that allows for the precise and efficient processing of sheet metal. With our high-performance machines, we can process sheets up to a size of 6000 x 2000 mm and a thickness of up to 30 mm, making us a reliable partner for demanding projects in a variety of industries.

Whether you need precise components for mechanical engineering, custom parts for the automotive industry, or innovative design solutions – we offer the right solution for you. Thanks to our modern laser cutting technology and dedicated team, we can deliver products of the highest quality that meet your exact requirements.

Contact us today to learn more about our laser cutting services and how we can assist you with your next project. We look forward to working with you to develop innovative solutions and bring your ideas to life.