Aluminum Profile Processing

Precision and Versatility in Construction

Aluminum profile processing is a key aspect of modern sheet metal working and plays a crucial role in various industries, from automotive to construction. Aluminum stands out for its light weight, corrosion resistance, and excellent workability, making it a preferred material for a wide range of applications. In aluminum profile processing, the goal is to transform raw profiles into precise components that meet the high standards required in various fields. On this page, you will learn about the services we offer in aluminum profile processing and how we turn your ideas into high-quality, functional products.

Consultation and Material Selection

The foundation of any successful aluminum profile processing project is careful consultation and material selection. Aluminum offers a wide variety of alloys and profile types, each differing in mechanical properties and workability. Our team of experienced engineers and technicians is here to help you make the best choice for your specific project.

We thoroughly analyze your requirements and provide comprehensive advice on the different aluminum alloys and profiles that may suit your application. Factors such as mechanical strength, corrosion resistance, weight, and workability are all considered. Our goal is to find the optimal material that meets both the functional needs and the economic framework of your project.

CAD Design and Construction

A critical step in aluminum profile processing is the precise design and construction of the components. State-of-the-art CAD software (Computer-Aided Design) is used, enabling the design of complex geometries and detailed structures. Our designers create 2D drawings and 3D models that reflect all aspects of the final component.

The 3D modeling process is particularly valuable, as it allows early visualization and optimization of the design. This ensures that the finished part is not only functional but also aesthetically pleasing. The CAD models serve as the foundation for subsequent processing steps such as milling, drilling, or cutting the aluminum profiles.

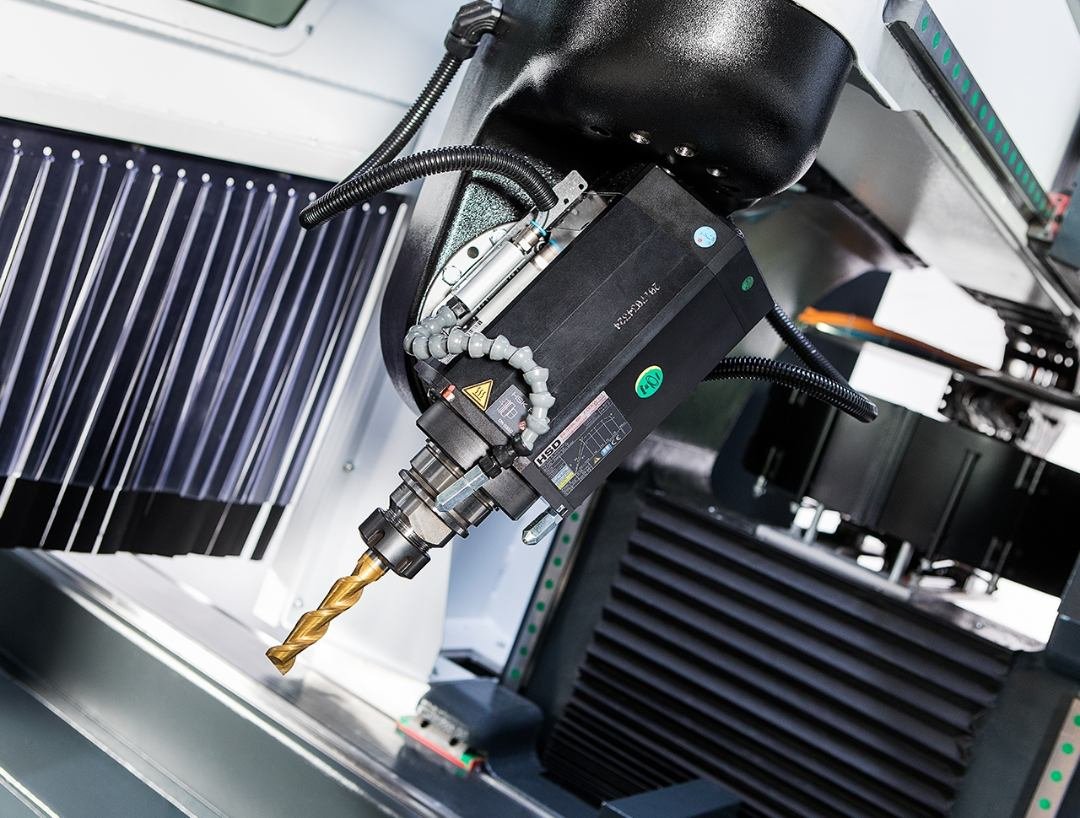

Milling and Drilling Aluminum Profiles

Milling and drilling are among the most important processing techniques in aluminum profile fabrication. These methods allow precise recesses, holes, and contours to be made in the material, which are essential for the assembly and functionality of the component.

Our modern CNC milling machines (Computerized Numerical Control) enable high-precision machining of aluminum profiles. Using CNC technology, we can produce complex and custom shapes with the highest accuracy and repeatability. Drilling aluminum profiles also requires great precision, especially when producing threads or preparing for screws. Our CNC drilling machines can efficiently and accurately create holes of various diameters and depths.

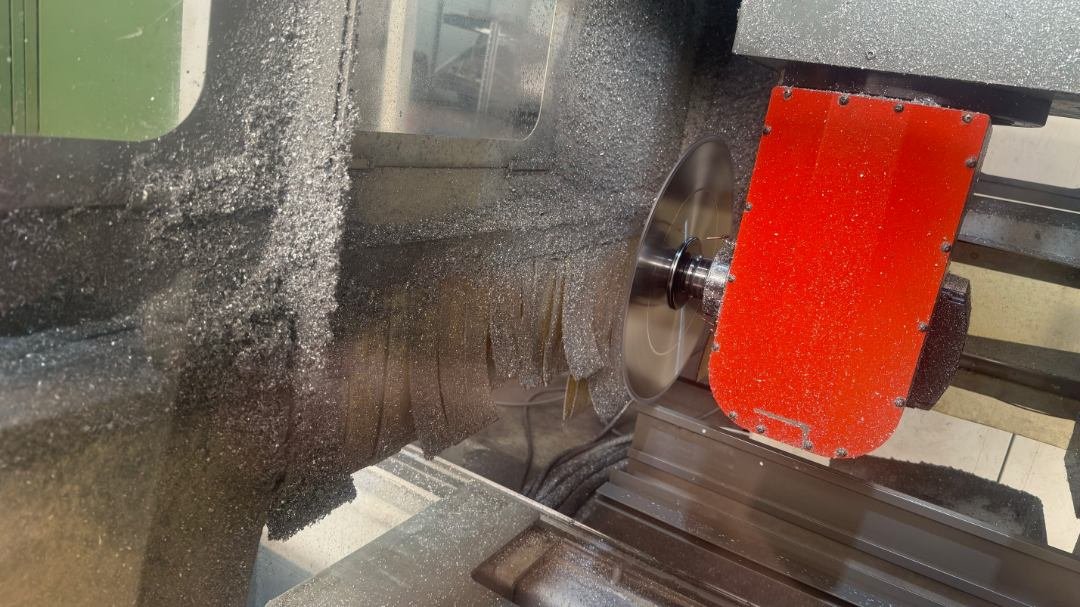

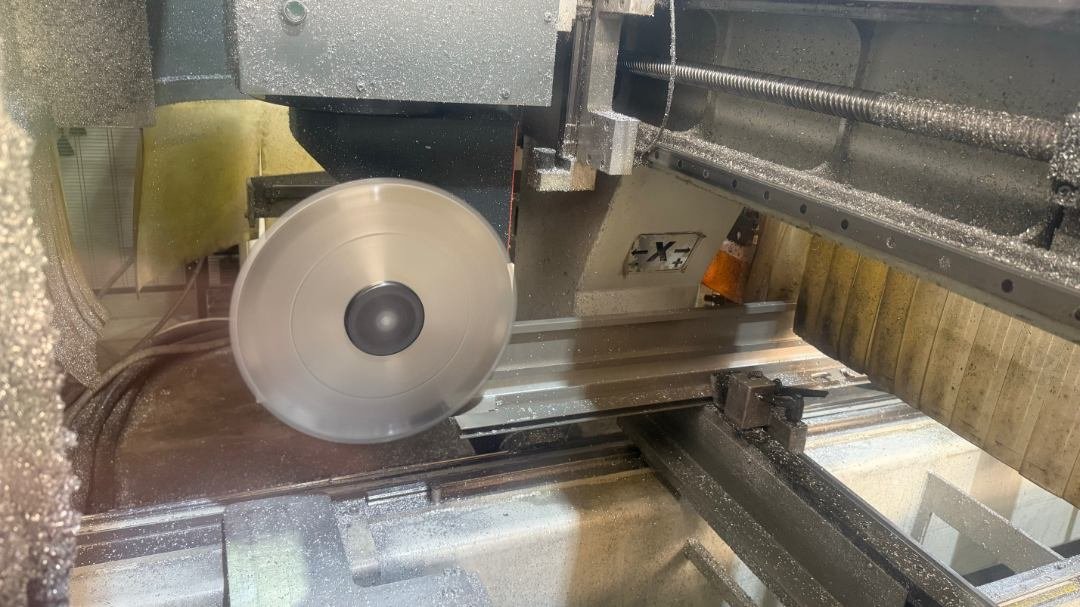

Cutting and Sawing Aluminum Profiles

Another key aspect of aluminum profile processing is cutting and sawing the profiles. These steps are necessary to shape the raw profiles into the desired lengths and forms. Various methods are employed, depending on the specific project requirements.

Sawing aluminum profiles is typically performed using specialized metal saws that offer both precision and efficiency. We use high-precision saws that allow for clean, burr-free cuts. For more complex shapes and contours, we use laser cutting machines, enabling us to cut aluminum profiles into almost any shape imaginable. This technology offers the advantage of making extremely fine and precise cuts without deforming or damaging the material.

Surface Treatment and Finishing

Surface treatment and finishing are important steps in aluminum profile processing to enhance the aesthetics and durability of the components. Aluminum provides an excellent base for various finishing processes that optimize both the functional and decorative properties of the material.

The most common surface treatments include anodizing, powder coating, and painting. Anodizing strengthens the natural oxide layer of the aluminum, improving corrosion resistance and providing a uniform, attractive finish. Powder coating offers a wide range of colors and surface textures that not only give the components an appealing appearance but also provide additional protection against environmental factors. Painting is another common method to refine aluminum profiles and give them a customized look.

Assembly and Construction

In many projects, the processing of aluminum profiles does not end with the production of individual components. Often, profiles need to be assembled into complete systems or units. Our services also include the assembly and construction of aluminum profiles, either as individual components or as part of a larger system.

Our experienced technicians ensure that all components are assembled precisely according to the required specifications. Various assembly techniques are used, such as screw connections, riveting, or bonding. Through close collaboration between our design and assembly teams, we ensure that all parts fit together seamlessly and meet the requirements for functionality and durability.

Prototyping and Series Production

Before mass production, it is often beneficial to create prototypes of aluminum profiles to test the design and functionality and make any necessary adjustments. We offer fast and precise prototyping to ensure that all aspects of the design are optimally realized.

After successful prototype development and validation, series production begins. Our production processes are designed to manufacture aluminum profiles efficiently and cost-effectively in large quantities without compromising quality. By using modern machines and technologies, we ensure consistently high quality that meets the requirements of various industries.

Quality Control and Documentation

Quality is our top priority. That's why we accompany every step of aluminum profile processing with comprehensive quality controls. From the design phase, we use advanced testing procedures to ensure that the design meets all requirements.

Throughout production, we conduct regular checks to ensure that specifications are met and that the quality of the components is maintained. After project completion, you will receive full documentation containing all relevant information about the aluminum profiles, the materials used, and the tests performed. This ensures transparency and traceability, so you can always be confident that you're receiving a product of the highest quality.

Conclusion

Aluminum profile processing is a complex and crucial process in modern sheet metal working. From initial consultation to design and processing, through to surface finishing and assembly, we offer comprehensive services tailored to your specific needs. With state-of-the-art technology, an experienced team, and a clear focus on quality and efficiency, we bring your ideas to life and deliver aluminum profiles that meet the highest standards. Trust our expertise in aluminum profile processing and let us successfully bring your projects to fruition together.