Sheet Metal Processing by Punching

Efficient and Versatile Technology for Mass Production

Punching is a core process in sheet metal processing that is widely used in many industries. It is one of the most efficient and cost-effective methods for producing sheet metal components in large quantities. Punching offers a variety of ways to create precise and repeatable shapes from sheet metal, making it indispensable in modern manufacturing. On this page, you will learn everything you need to know about punching, its advantages, and the various areas of application.

What is Punching?

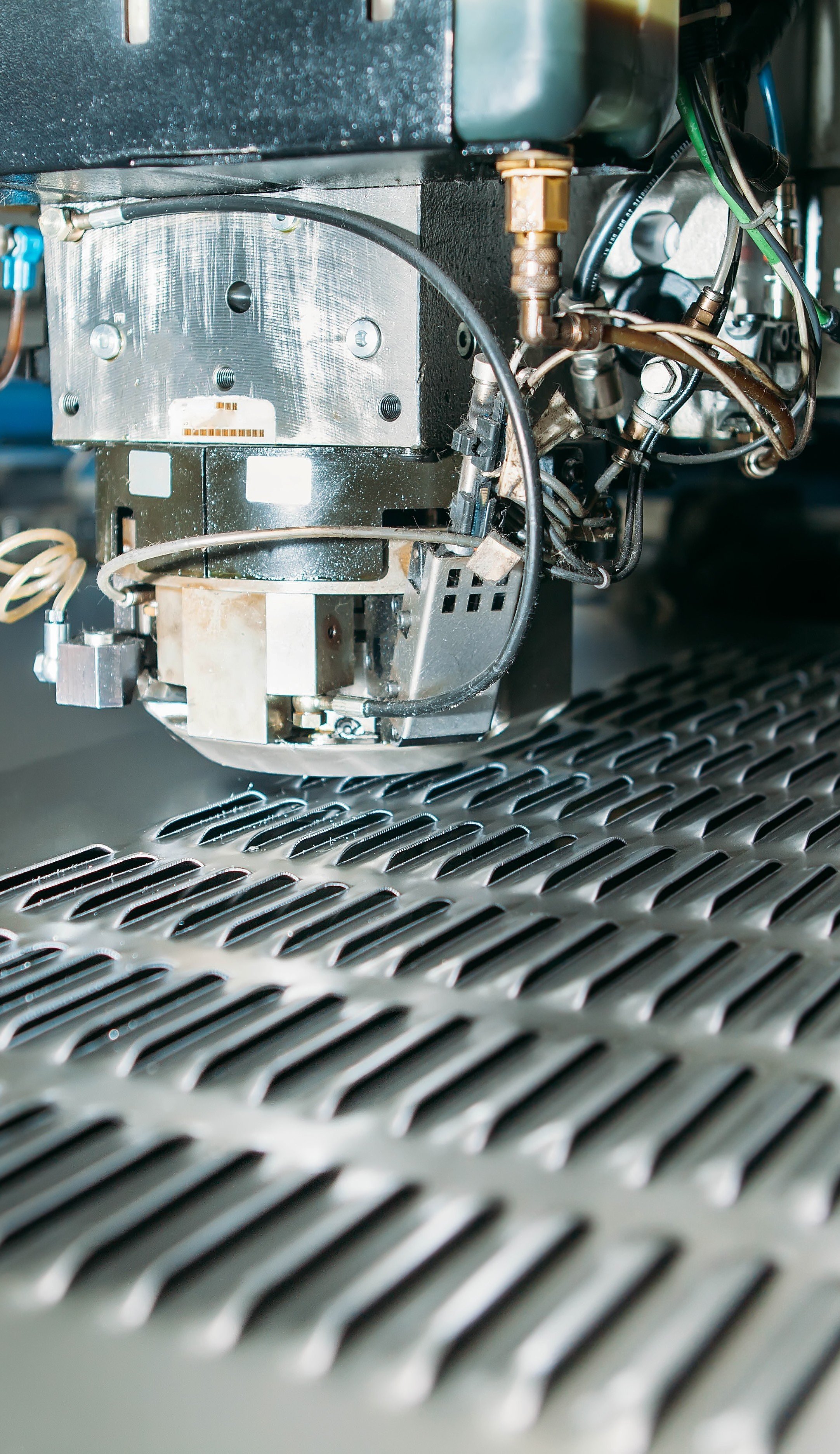

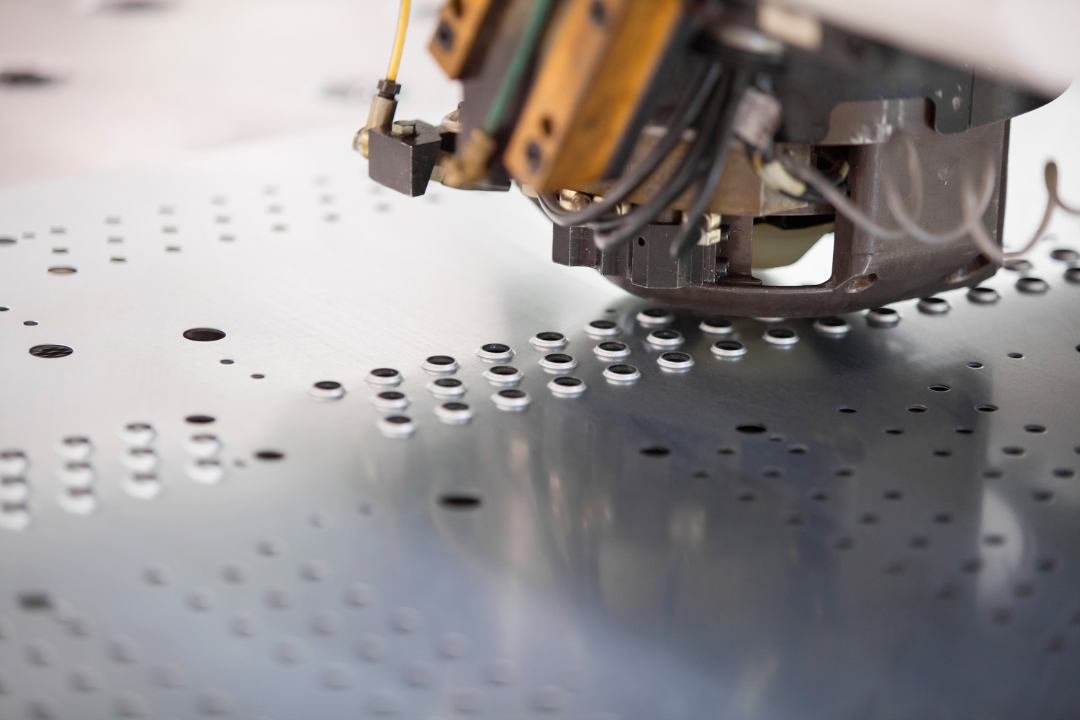

Punching is a mechanical processing method in which flat sheet metal is cut or embossed into a desired shape using tools and machines. It is a cold forming process in which the sheet is processed in a single step using a cutting tool (the punch). The punch exerts high pressure on the sheet, separating the material along the contours of the tool.

The process can be used for cutting, punching, embossing, or bending sheet metal. Depending on the requirement, different punching methods are employed, including full cutting, where the material is completely separated, and fine blanking, which provides particularly precise and burr-free cutting edges.

Advantages of Punching in Sheet Metal Processing

Punching offers numerous advantages, making it a preferred choice for mass production and the manufacturing of sheet metal parts:

High Efficiency and Speed

One of the biggest advantages of punching is the speed at which large quantities of parts can be produced. With the use of high-performance punching machines, thousands of parts can be manufactured precisely and repeatedly in a short time. This makes punching especially suitable for serial production.

Cost-Effectiveness

Compared to other processing methods, punching is highly economical, especially for large quantities. The tool costs are quickly amortized with high production volumes, leading to low per-unit costs. Additionally, material consumption during punching is minimal, as the process is very precise and produces little waste.

Versatility

Punching is suitable for a wide range of applications. It can be used to create various shapes and designs from sheet metal, from simple holes and cutouts to complex, three-dimensional embossing. Additionally, various metals, such as steel, aluminum, copper, and brass, can be processed, making the method highly flexible.

High Precision and Repeatability

The precision of punching is another significant advantage. The process allows the production of components with very tight tolerances that maintain consistent quality in mass production. This is especially important in industries like the automotive sector, where exact dimensions are critical.

Integration into Automated Processes

Punching machines can easily be integrated into automated production lines. This allows for fully automated production, where the sheets are automatically fed, punched, and the finished parts removed. As a result, production processes are further accelerated, and costs are reduced.

Tools and Machines for Punching

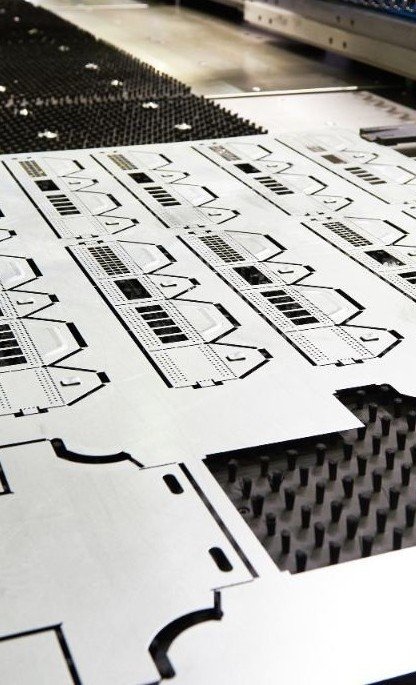

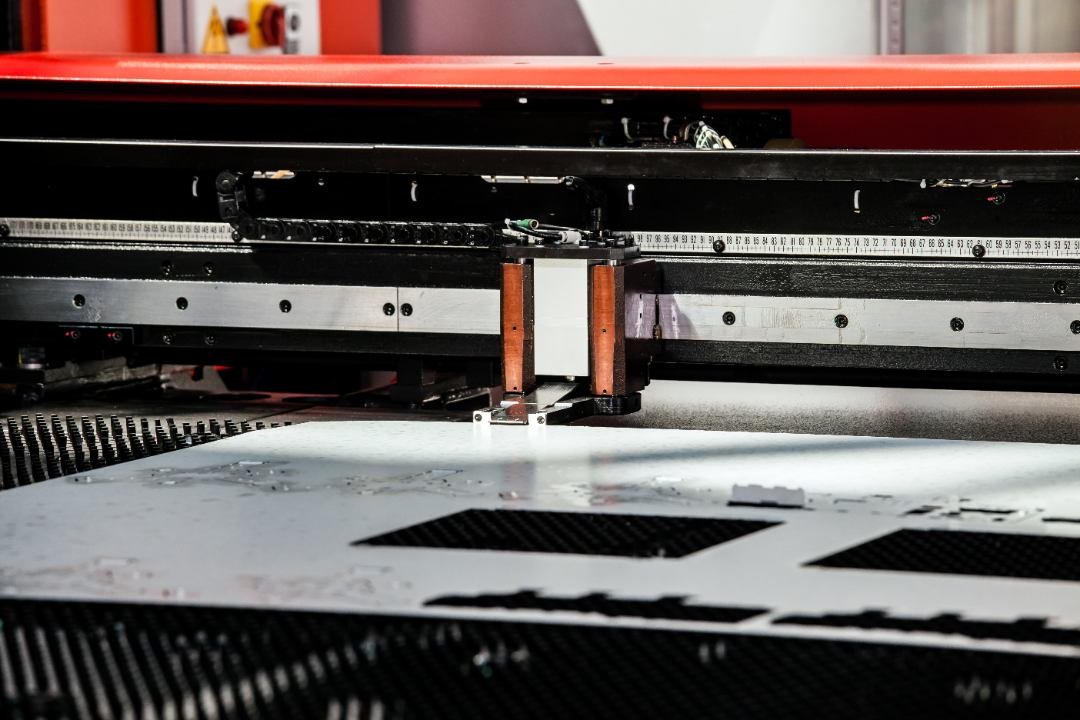

The quality and efficiency of the punching process depend significantly on the tools and machines used. Punching tools typically consist of an upper part (the punch) and a lower part (the die), which work together to cut or emboss the sheet metal. The tools are made of high-strength materials such as hardened steel to withstand the high stresses during the punching process.

Modern punching machines are highly advanced, computer-controlled systems that enable the production of even complex parts with high speed and precision. CNC punching machines can fully automate the punching process and carry out a variety of processing steps in a single operation. This reduces production times and increases manufacturing efficiency.

The Future of Punching

Punching has continuously evolved in recent years and will continue to play a central role in sheet metal processing in the future. New materials and technologies, such as fine blanking, are expanding the possibilities of the process, enabling even more precise and complex applications. The integration of punching processes into highly automated production lines is also being further advanced to increase efficiency and cost-effectiveness.

With the growing focus on sustainability in the industry, punching is also gaining importance, as it is a material-efficient process that produces minimal waste. This helps reduce environmental impact and optimize the use of resources.

Conclusion

Punching is one of the most efficient and versatile methods in sheet metal processing. It enables the fast and cost-effective production of sheet metal parts in large quantities without sacrificing precision and quality. With its wide range of applications across various industries, high efficiency, and advanced technological developments, punching remains an indispensable technique in modern manufacturing. Whether in the automotive industry, mechanical engineering, or electronics, punching offers the perfect solution for the mass production of high-quality sheet metal parts.