Stud Welding

Precision and Efficiency in Sheet Metal Fabrication

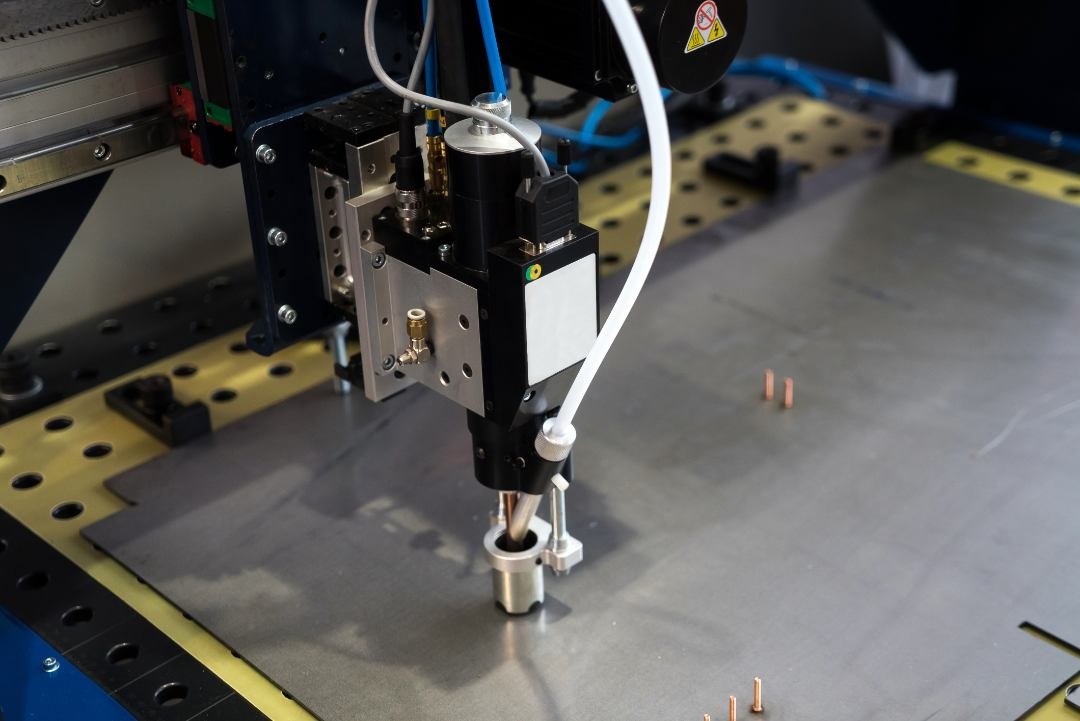

Stud welding is a highly specialized welding process in sheet metal fabrication, known for its efficiency and precision. It enables the permanent and reliable fastening of studs, pins, sleeves, or similar components to metal surfaces without the need for perforations or pre-drilling. This technique is indispensable in many industries, from automotive and mechanical engineering to construction and electrical industries. On this page, you will learn about our stud welding services, the different processes we use, and the benefits of this technique for your projects.

What is Stud Welding?

Stud welding is a process where studs, pins, or other fastening elements are welded directly onto a metal surface. The process uses an electric arc to melt the end of the stud, which then fuses with the metal surface, creating a strong, permanent bond capable of withstanding high loads. Unlike other fastening methods like screwing or riveting, stud welding has the advantage of not requiring pre-drilling or perforating the materials, preserving the integrity of the materials and eliminating additional processing steps.

Unlike traditional painting methods that use liquid paints, powder coating requires no solvents. This makes the process more environmentally friendly and safer to apply. Additionally, powder coating produces a thicker, more uniform layer that offers better protection and lasts longer.

Application of Stud Welding

Stud welding is used across various industries, particularly where fast, secure fastening of components onto metal surfaces without pre-processing is required:

Automotive Industry

In the automotive industry, stud welding is often used to attach body and structural components. It is essential for securing parts like cable channels, wires, metal sheets, or cladding elements to the car body, enabling quick and reliable assembly that withstands high mechanical stresses.

Mechanical Engineering

Stud welding is a crucial process in mechanical engineering for attaching components to machine housings, frames, or supports. It ensures a permanent connection that remains secure even under extreme conditions. This process is versatile enough to weld both small studs for fine mechanical parts and large studs for heavy machinery components.

Construction Industry

In the construction industry, stud welding is used for attaching steel beams, facade elements, or railings. It is particularly efficient in metal construction, where large steel structures are used, offering a fast and reliable method of attaching fastening elements.

Electrical Industry

In the electrical industry, stud welding is used to create electrical contacts, grounding studs, or fastening points for cables and wires. The precise and clean attachment of the studs is crucial to ensuring safe and reliable electrical connections.

Stud Welding Processes

We use various stud welding processes, selected based on the material, application, and project requirements. The most common methods include capacitor discharge stud welding, drawn arc stud welding, and arc stud welding.

Capacitor Discharge Stud Welding

This process is primarily used for thin sheets and small studs. The stud has a small tip that melts when current is applied, initiating the arc. The arc melts the stud's end and a small area of the metal surface, allowing the stud to fuse with the sheet upon contact. This method is characterized by its speed and the ability to attach studs to very thin sheets without penetrating or deforming the material.

Drawn Arc Stud Welding

This method is used for larger studs and thicker sheets. The stud is first placed on the workpiece and then mechanically lifted as an arc is initiated. The arc melts the stud’s end and the contact surface of the workpiece. The stud is then lowered back onto the workpiece, bonding with the molten surface. This versatile method allows stud welding on various materials, from thin sheets to thick steel plates.

Arc Stud Welding

This process is used for large studs and high-strength connections. A strong arc is generated between the stud and the workpiece, melting the stud's end and the metal surface. The stud is pressed into the molten pool, forming a strong and permanent bond. This method is ideal for applications with high strength requirements, such as steel construction or heavy industry.

Quality Control and Post-Processing

Quality and precision are at the forefront of what we do. After each welding operation, we conduct thorough quality control checks to ensure that all studs are securely and permanently attached to the workpiece. This includes visual inspections as well as, where necessary, non-destructive testing methods to guarantee the integrity of the welds.

We also offer post-processing services, such as smoothing or polishing the surface of the components, ensuring a flawless appearance. This ensures that the final parts are not only functional but also visually appealing.

Conclusion

Stud welding is an essential process in sheet metal fabrication that enables fast, efficient, and permanent attachment of studs and pins to metal surfaces. With methods such as capacitor discharge stud welding, drawn arc stud welding, and arc stud welding, we offer tailored solutions for your specific needs. Whether in the automotive industry, mechanical engineering, construction, or electrical sectors – stud welding provides the perfect combination of speed, efficiency, and high strength. Trust our expertise and experience in stud welding and let’s successfully implement your projects together.